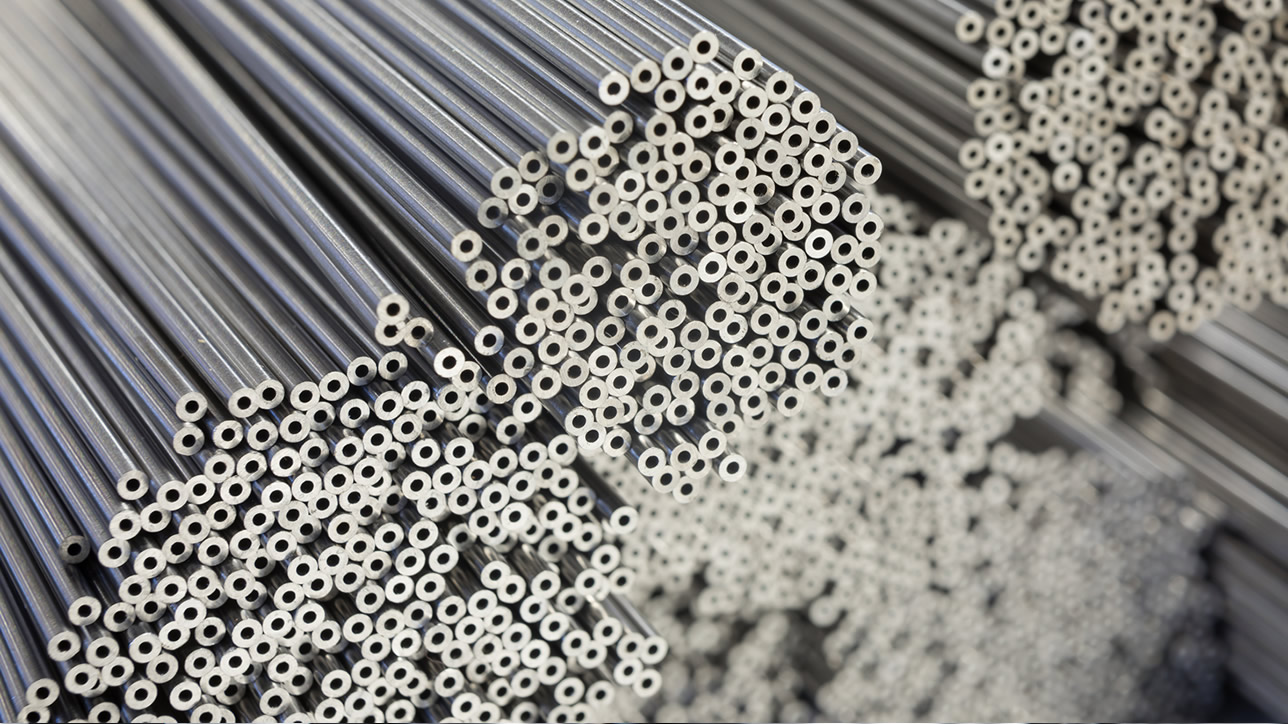

Medical Tubing Materials

High-Quality Stainless Steel Alloys

Stainless steel is the material of choice for the Medical Device industry because of its good formability, good corrosion resistance, and minimal distortion when heat treated.

We have extensive experience with processing a select group of high-quality stainless steel alloys that allows us to optimize cost while meeting or exceeding your requirements. Our core materials:

- 17-7

- 304/304L

- 316/316L

- 321

Looking for high-nickel alloys or other materials? See Tubing Materials for Controlled Industrial markets.

Stronger Material + Easier to Machine

As demand increases for smaller, longer tubes with thinner walls, 17-7 gives you the strength to optimize your design compared with traditional 304 stainless steel.

This stainless steel alloy (also called 17-7 PH, UNS S17700, or AISI 631) has a chemical composition of 17% chromium and 7% nickel (“17-7”). But the “secret sauce” is a small addition of aluminum that gives this material interesting properties in both cold-worked and precipitation-hardened conditions.

Compared to 304 stainless steel, 17-7 has similar corrosion resistance but has several advantages. In a similar cold-worked condition, 17-7 has increased strength and better machinability than 304. When heat-treated, 17-7 exhibits increased hardness and tensile strength that can’t be achieved by cold-working alone.

Other benefits of 17-7:

- Higher tensile strength

17-7’s tensile strength above 160 ksi provides good strength and dimensional stability when machining. - Improved Machinability

In cold-worked condition or annealed, 17-7 machines better and faster than 304 because of its high tensile strength. - Weldability

17-7 has excellent weldability using laser or tungsten inert gas (TIG) welding. - Magnetic Permeability

In annealed condition, cold-worked condition, or heat-treated condition (RH950 or TH1050), 17-7 is slightly ferromagnetic.

Tensile Strength: Spec for Success

17-7 tubing does not follow metal strip and wire specifications because it fractures when straightened at the tensile strengths in the wire specifications. We recommend the following tensile specifications for 17-7:

- Condition A (Annealed)

- 145 ksi MAX tensile strength

- Can be heat-treated to RH950 or TH1050

- Condition C (As drawn)

- Not all tubing can be manufactured to meet the condition C requirement of 200 ksi MIN tensile strength as called out in strip and rod specifications. The straightening process requires a slightly lower tensile target.

- Target a tensile strength of 160 ksi MIN

- Heat treated to CH900 process

- Not all tubing can meet the requirement of 240 ksi MIN as called out in strip and rod specifications. The straightening process requires a slightly lower tensile target.

- Target a tensile strength of 200 ksi MIN

Other recommendations when using 17-7:

- Heat treated RH950 and TH1050

Complete heat treating after the component is fabricated - Vacuum heat-treating

Use a vendor that has significant experience with heat treating 17-7 materials - Post-heat-treating

If you need bright parts, we can do mechanical polishing or electropolishing - Tensile strength

Use a numerical tensile requirement, not a hardness specification. Measuring hardness is challenging on small-diameter tubing due to the size and geometry of the tubing. - Measure tubing being tensile tested

A shift in the tolerance range can impact the tensile calculation significantly. If you use the nominal ID and OD specifications versus actual measurements, your calculations may be off significantly.

Tubing

Get Prototyping Tubing Fast

Select sizes are available in small quantities for quick delivery through Chamfr.com.

Shop Now